| Industry | Project / Location | Country | Customer | Year |

| Power | Final filters for equipment for Siemens gas power plant | Armenia | Max Streicher / Siemens | 2020 |

November 2020

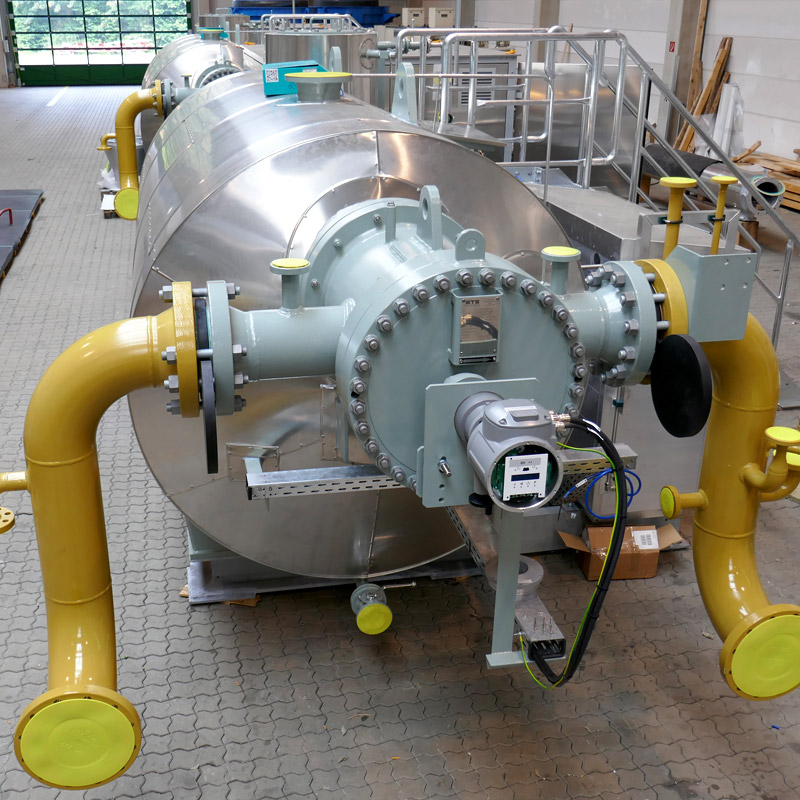

Our partner MAX STREICHER Anlagentechnik GmbH & Co. KG has executed with us, Thielmann Energietechnik GmbH, four fine dust filters for fuel gas for gas power plants in the Middle East on behalf of Siemens AG.

The equipment of the new filters includes electrical shut-off & venting systems as well as electrical measuring devices for pressure, temperature and filter contamination.

The surrounding piping and the two filters themselves are electrically heated and insulated. This prevents the gas from condensing out in the piping. The scope of the order included the entire planning, fabrication, assembly, and transport-ready packaging in deep-sea containers.

The plant went into operation in 2020.

| Technical Data: | |

|---|---|

| Product | Final Filter |

| Type | VSFA-V-PZ 2.600.30.250.1 |

| Quantity | 4 pc(s) |

| Code | ASME |

| P design | 30 bar |

| T design | 0 bis 170°C |

| Flow rate VN | 76.705 Nm³/h |

| Efficiency | 99,5% >2µm |

| Weight | 1,3 tons |