| Industry | Project / Location | Country | Customer | Year |

| GDRM/PRMS | Gascade – GDRM compressor station Radeland 2 | Germany | Gascade | 2018 |

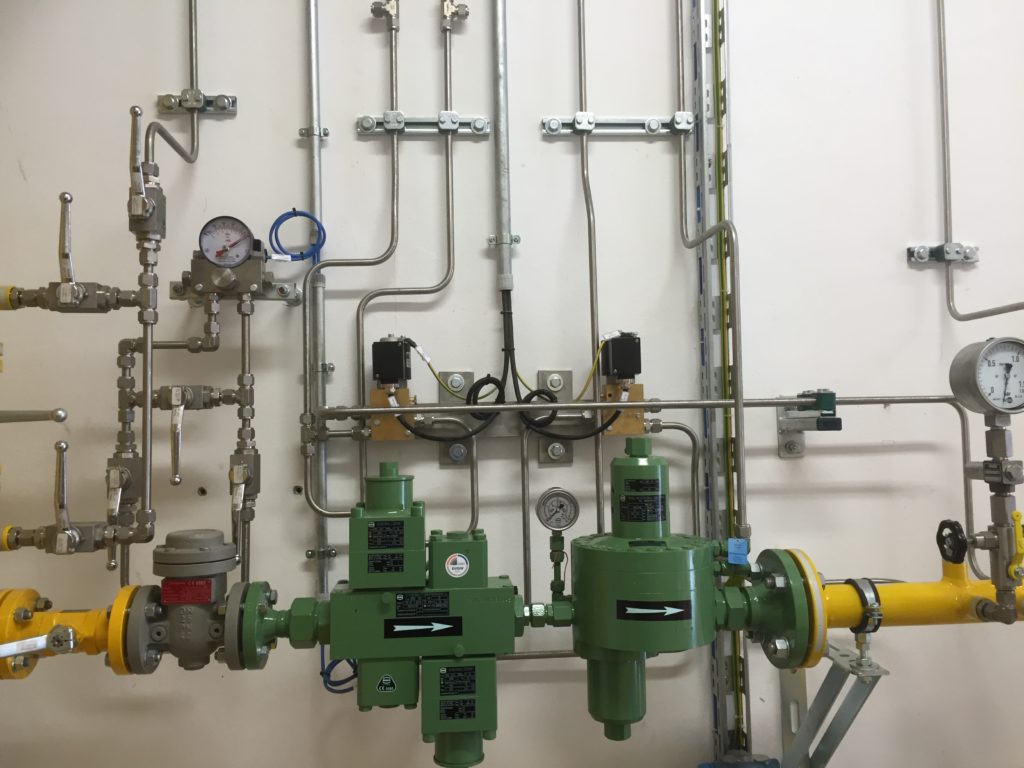

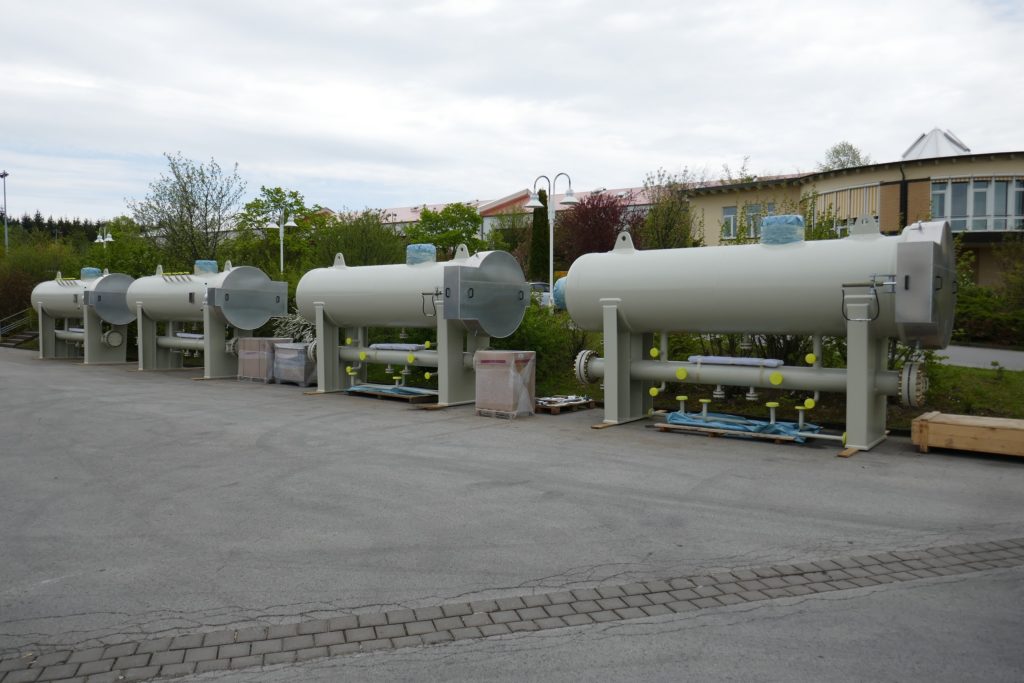

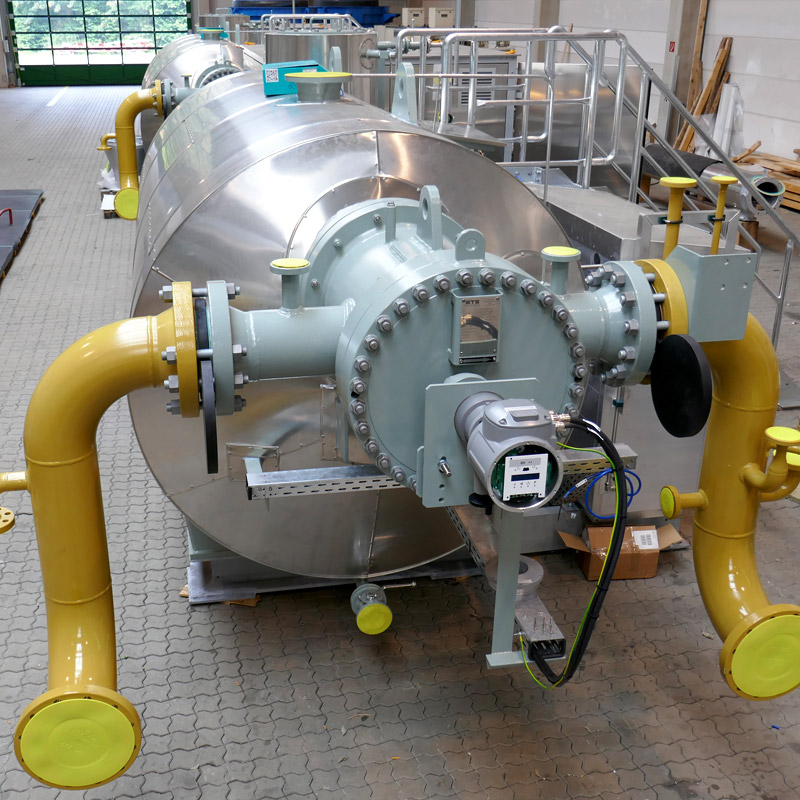

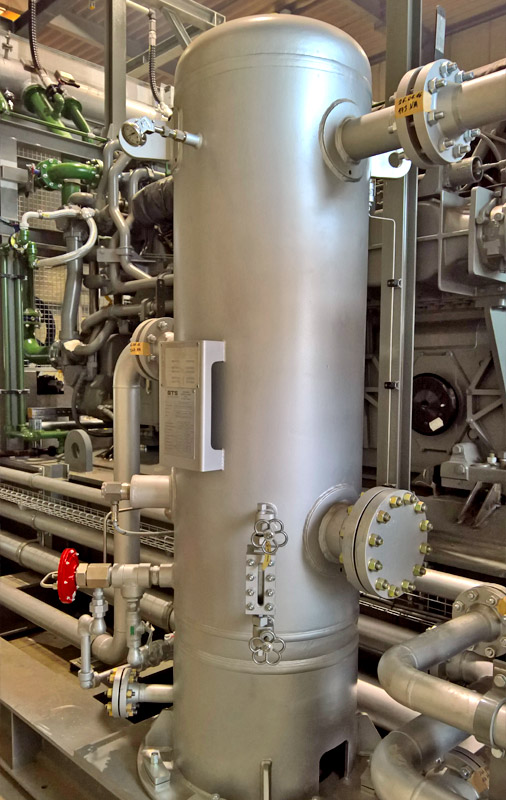

South of Berlin in Baruth, Brandenburg, GASCADE has built Radeland 2, one of the most modern compressor stations in Western Europe. Since 2021, the facility has been part of the infrastructure for the EUGAL (European Gas Link). On the site, which covers more than ten hectares, three compressors raise the pressure of the gas back up to around 100 bar after about 270 kilometers of transport on the EUGAL.Thielmann Energietechnik will deliver four horizontal dust-liquid separators in February 2019..

| Technical Data: | |

|---|---|

| Product | Dust-Liquid Separator |

| Type | VSFA-H-CV 27.1300.100.500.3 |

| Quantity | 4 pcs |

| Code | AD 2000 + CE // BASF |

| P design | 100 bar |

| T design | -20 / + 60 °C |

| Flow rate VN | 550.000 Nm³/h |

| Efficiency: | 99,9 % > 1µm |

| Weight | 12 tons |

| Specials | Safety Factor 1,7 Vane Package with Agglomerator (SS) |